Modern mass timber makes its debut in Iowa

The modest Midwestern city of Des Moines, Iowa (the state’s capital), sits nestled among cornfields that are the agricultural engine for much of the country. Opposite the business district, separated by the Des Moines River, is an area known as the East Village, where factories and warehouses that once thrived are being repurposed into restaurants, businesses and housing, after an era of decline due to suburban migration. Here, a one-minute walk from the city’s historic City Hall, the first modern mass timber building in Iowa is due to be completed in April 2019 – also becoming the first dowel laminated timber (DLT) office structure in North America.

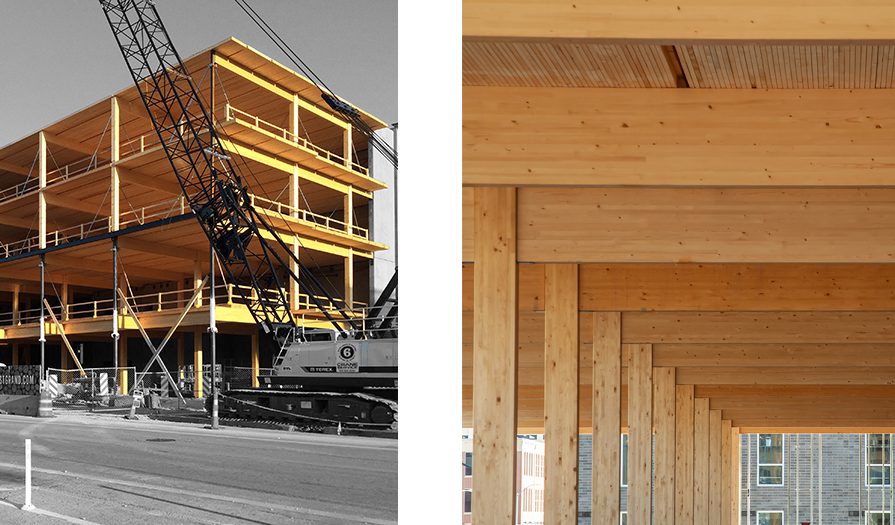

With a nod to its turn-of-the-century wood and masonry elders, 111 East Grand will feature fully exposed mass timber on the interior, a showcase for DLT. This innovative project joins several other new buildings in the area; in 2013, a mixed-use residential steel and hollow-core precast building was erected, followed by another mixed-use residential structure of similar construction. An ongoing collaboration between the development team, led by JSC Properties Inc., Neumann Monson Architects and Ryan Companies (general contractor), resulted in a willingness to “push the envelope” – hence, this newest project. Four storeys (60 ft. in height) will provide 65,000-sq.ft. of space, with the first level home to retail and restaurants, while the upper three floors house various office spaces. The ground level is wrapped with storefronts, visually connecting vehicular and pedestrian traffic to the exposed structural frame.

The design team went through an extensive interview process with various subcontractors, selecting StructureCraft Builders as the design-build timber partner during the early schematic stages of design; StructureCraft had previous experience working in the Midwest, recently completing T3, a mass timber office building in Minneapolis, MN (a Wood Award “Citation” winner in 2016). Visiting this precedent helped the developer team confirm that mass timber was the right direction to go. DLT, or Dübelholz in Europe, was chosen as the floor and roof slab system. This mass timber product utilizes a series of dimensional softwood lumber strands fastened together face-to-face, with a hardwood dowel hydraulically inserted (perpendicular) to create a strong friction-fit mechanical bond. This system has been used in Europe for the past couple of decades and just recently found its way to North America.

Construction began the summer of 2018, with Ryan Companies erecting a series of precast panels that form the service core and provide the primary lateral support for the building. The subsequent arrival of the mass timber in early August enabled StructureCraft to be the only trade on site during its erection. Each individual column, beam and panel were assigned a number and shipped to the site in chronological order for erection. Akin to a basswood model in architecture school, the 13 structural bays were erected east to west in approximately six weeks with a crew of eight, including two supervisors and six local carpenters.

Glulam columns and beams (spruce) were shipped from Austria. The 2×8 DLT floor panels and 2×6 roof panels (SPF) were fabricated in-house by StructureCraft, at the first plant to produce DLT on a large scale in North America. Early on, Neumann Monson expressed their desire to integrate the electrical conduits with the timber structure. The inherent linear laminations of DLT aided in the creation of a 4×4-inch channel using shallower boards at the panel edges. In addition, StructureCraft worked closely with the architect to develop details which “socket” the beams into the columns, creating an aesthetic that celebrates the wood and reduces the amount of exposed metal and intumescent paint required to achieve the one-hour rating between the first and second levels.

Future tenants eagerly await their move-in date (including Neumann Monson Architects and Ryan Companies) and the opportunity to be in a space that offers visual, tactile, olfactive and biophilic connections to its inhabitants. Sensibility as much as sustainability are growing ever more imperative in the construction industry. The current global situation strongly suggests an exploration of alternative construction methodologies, and depending on the market, a timber building’s structural cost is similar to that of steel or concrete. Properly designed, they can accommodate the distribution of services tastefully. They require neither dropped ceilings nor wrapping of beams and columns. Continued innovations in engineering have enabled these structures to perform very well under fire conditions and to be erected quicker than any other type of structure. 111 East Grand aims to embody these values and help to fuel the timber momentum that has already begun to make its way across North America.

Architect

Neumann Monson Architects

Des Moines, IA

Structural Engineer

Raker Rhodes Engineering

Des Moines, IA

Mass Timber Structural Engineer and Builder

StructureCraft Builders

Vancouver, BC

General Contractor

Ryan Companies

Clive, IA

M.E.P.

Baker Group

Ankeny, IA

Photography

Neumann Monson Architects, StructureCraft Builders