Providing flexible timber solutions for commercial long-span floor and roof applications

Hans-Erik Blomgren, PE, SE, P.Eng., Struct.Eng.

INTRODUCTION

The application of CLT panels as floor and roof structures for commercial buildings in North America is advancing rapidly, driven by the aesthetic appeal of exposed wood, faster construction times and carbon storage benefits. But the gap between market interest and defined market solutions often can be significant. In order to be competitive in the marketplace compared to established concrete and steel options, the CLT architect and engineer are challenged to bring a high level of optimization to floor plate designs that reduce cost -without compromising structural, acoustic or fire performance. This is especially the case for open office and education buildings, where the program requires floor spans between column lines that are larger than traditional timber framing approaches can efficiently achieve.

BACKGROUND:

CLT FLOOR & ROOF SPANS

Katerra opened the highest-capacity CLT factory in the U.S. in 2019 and began delivering CLT for use as floors and roofs on multi-family residential projects and office buildings. For typical multi-family buildings, CLT spans ranging from 12–20 ft. are required; for this project type, three- or five-ply Katerra CLT panels are well suited to span between bearing walls; however, Katerra’s first office and education mixed-use building, the Catalyst Building in Eastern Washington State, required a 30-ft. floor span between column lines. A CLT flat panel is not capable of spanning this distance, even when increased in thickness to seven- or nine-ply.

RIB PANELS DEFINED

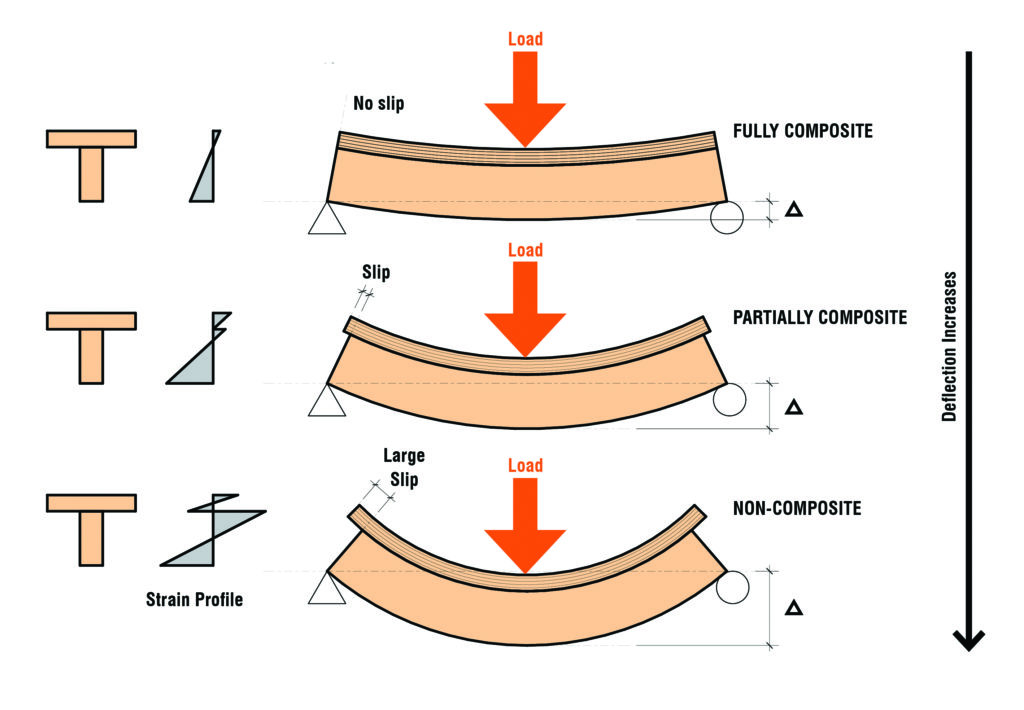

Posed with this challenge, along with a desire to maximize the use of its CLT product, Katerra saw an opportunity to increase the span of its product beyond 20 ft. by introducing glulam beams or “ribs” to the underside of each panel, spanning parallel with its long (strong) direction (Figure 1). The efficiency of the resulting product is achieved when a rigid and strong structural connection between the CLT and glulam ribs is provided, which enables the full cross-section to work compositely.

Calculations demonstrate the strength and stiffness of a rib panel can increase nearly four-fold when full composite action is achieved (Figure 2). This optimized use of wood fiber is the primary advantage of a rib panel. As an example, the Catalyst Building rib panel has a span-to-depth ratio of 15.5:1, which is equivalent to a benchmark composite steel floor beam for the same span and load, while being 40 percent lighter in weight. It is clear to see the potential rib panel products have to expand mass timber floor spans well beyond the 20-ft. limit of five-ply (Figure 3).

PRODUCT DEVELOPMENT

With the project benefits of the rib panel identified, Katerra’s engineers and manufacturing team began a product development effort to define the most suitable materials, method and process of compositely fastening glulam ribs to the underside of CLT. The selected connection method is achieved by: 1) applying an adhesive to the top of each rib; 2) laying the CLT panel on top; and 3) installing partially threaded screws through the joint to clamp the surfaces closely together and to spread out the adhesive, covering the full surface area of the mated parts (Figure 4). This process has been dubbed the “Screw-Press-Glue” method and has undergone prior research and testing in Europe [1]. The resulting manufacturing process allows for a rib panel to be fully assembled in less than 20 minutes (Figure 5). The production for the Catalyst Building was able to stay ahead of the construction site schedule by producing up to 18 30×10-ft. rib panels in a single factory shift.

BUILDING DESIGN INTEGRATION

The five-storey, 150,000-sq.ft. Catalyst Building provided a valuable “real project” opportunity to ensure the rib panel product design is integrated with the architectural and building operations requirements. To achieve the overall acoustic sound transmission requirements through the floor plate and limit human footfall vibration perceptibility to acceptable levels, a minimal 2-in.-thick gypcrete topping mass and acoustic underlayment were placed on top of the CLT (Figure 6). The CLT panels transfer horizontal wind and seismic diaphragm forces directly, which allowed the topping materials to be non-structural. The rib panel was designed for a one-hour fire resistive rating through charring of the exposed CLT and glulam surfaces; this exceeded the minimum requirements of the Catalyst Building Type IV Heavy Timber Construction Type.

The void space between each rib provides ample room for building services, including conduit, sprinkler pipes, lighting and small ductwork to route above the bottom elevation of the ribs (Figure 7). In certain locations, a 4-in.-diameter horizontal penetration through the ribs was provided for sprinkler lines running transverse to the rib panel span direction.

CODE ACCEPTANCE

The Catalyst Building is a first-of-its-kind application of rib panels in the U.S. The project was designed and permitted under the 2015 International Building Code. Materials and methods of design for timber-timber composite members are not prescribed in the code. Recognizing this, Katerra engineers worked with the building official to ensure that full-scale destructive load testing would be acceptable to demonstrate rib panels are safe (Figure 8). It is worth noting, this testing was performed to recognized standards to help ensure the acceptance of rib panels on future projects in different regions of North America. Table 1 provides a summary of the code compliance design criteria that were satisfied. More technical details regarding rib panel product testing can be found in Katerra’s 2020 World Conference on Timber Engineering paper [2].

CONCLUSION

The Katerra Rib Panel has been developed to provide an efficient solution to increase the span capability of CLT floors in commercial building applications. The rib panel span, size and cross-section dimension are readily customizable for a creative variety of project-specific applications. The manufacturing process and performance of the product has been demonstrated on the Catalyst for a 30-ft. span. Performance has been validated through full-scale destructive and non-destructive testing to recognized standards. This validation can be used as justification for code acceptance on future projects.

References

[1]

Bratulic K. et al.: Investigations Concerning Screw-Press-Gluing of Assemblies with CLT, INTER 52-18-01, 2019.

[2]

Blomgren H. – Development Testing and Application of Mass Timber Composite Rib Floor Panels for Office Buildings, World Conference of Timber Engineering, 2020.

[3]

CCIP-016 A Design Guide for Footfall Induced Vibration of Structures, M R Willford, The Concrete Centre, 2007.

About the author

Hans-Erik Blomgren manages the development and certification for Katerra’s cross-laminated timber product line manufactured at a 270,000-sq.ft. factory in Spokane Valley, WA. As well, he leads Katerra’s efforts to technically justify and test cross-laminated timber panel assemblies and systems for code compliant fire, structural and acoustic use. Hans-Erik represents Katerra on the APA PRG 320 Cross-Laminated Timber and American Wood Council Wood Design Standards code development committees.