The challenges of noncombustible exit enclosures and wood buildings.

Steven Street and Veronica Madonna

The Ontario Building Code (OBC) 2012 amendment, which came into effect in January 2015, allows for combustible construction (wood) to be used in buildings up to six stories for both Residential (Group C) and Business and Personal Services (Group D) occupancies. These code provisions provide another solution for advancing mid-rise scale construction in city centers across Ontario, with similar mid-rise provisions being contained in the National Building Code of Canada 2015 used elsewhere in the country.

With the provisions allowing for mixed major occupancies – such as first- and second-story retail, restaurants, and other permittable commerce activities, – this creates a holistic approach to community planning while addressing critical strategies toward carbon reduction and providing increased housing stock. Bringing much-needed density into livable, established, and walkable communities has been the goal of city planners in urban centers for many years. Infrastructure is normally in place, and, typically, these are transit-connected neighborhoods. With a more human scale height and size, mid-rise buildings fit into existing neighborhoods with minimal impact.

One challenge for the construction of five- and six-story wood buildings has been that the OBC 2012 amendment provisions require exit stair enclosures to be made of noncombustible materials.

The addition of noncombustible enclosures poses challenges in designing a building, not only from an architectural and structural engineering point of view, but also from a construction approach.

Building designers need to carefully understand how the wood structural systems will interact with vertical shafts built of stiffer materials, by detailing them correctly and by calculating the expected cumulative vertical movement of the structure. This is important when considering and maintaining the performance and integrity of the building envelope. Equally, vertical movement needs to be anticipated and designed to isolate stiffer materials from a more ductile wood structure. Acoustic performance must be considered in the design phase. Isolating and decoupling the stiffer exit stair shaft walls cuts flanking noise transmission and maintains the required sound transmission class. From the construction perspective, noncombustible exit stair enclosures require another trade on-site; this may have an impact on the build schedule and incur additional construction costs.

As interest and confidence in mass timber develops, and with supply and use increasing, mass timber has caught the attention of design teams and developers who are exploring all-wood mid-rise buildings. This approach requires introducing an alternative solution that uses combustible construction in lieu of noncombustible materials for the exit stair enclosures. The alternative solution application that’s submitted to the Authority Having Jurisdiction (AHJ) will need to be shown to achieve the level of performance required by the acceptable solution in Division B of the current OBC 2012. (The OBC is objective based and will therefore allow for variations to the prescriptive acceptable solutions.)

Engaging a code consultant on the design team from the outset is prudent, as early discussions with the AHJ are encouraged for buildings of this type where combustible construction is proposed for the exit stair enclosures and fire separations instead of noncombustible materials.

Many all-wood buildings have been proposed and are currently under design and construction in Ontario. Six-story, mixed-use, infill residential buildings that are built using lower embodied carbon materials and achieving Passive House standards and net zero carbon are the vision of many development teams. The use of prefabricated wood structural systems like light wood-frame, mass timber, and factory built offers many benefits. Good repeatable architectural design in combination with structural systems that provide optimized unit layouts, like the R-Hauz Vertical 6 project in Toronto, is key. This six-story urban infill development, constructed entirely out of CLT, including the exit stair enclosures, sets an important precedent.

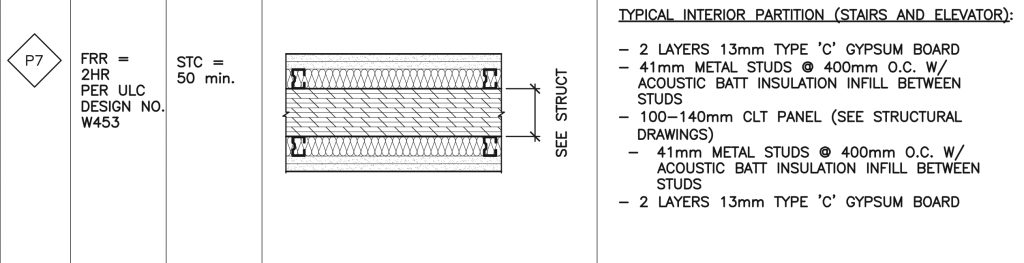

The CLT exit stair enclosure was approved through an alternative solution application, one of several required for the R-Hauz project. In replacing the required noncombustible assemblies, the CLT was protected by gypsum board on both sides of the assembly and achieved a two-hour fire rating, which exceeded the level of performance of 1.5 hours required by the OBC wall assembly detail for the CLT exit stair enclosure.

Many of the urban cores that make up our towns and cities across Ontario contain two- and three-story buildings.These buildings constructed in the early 20th century often have street-level retail, commercial, and restaurant spaces, with living space above. Buildings of this typology present an invaluable opportunity to add more density to vibrant and established communities by adding more stories to our existing building inventory by “topping up.” Preserving existing building façades and adding to our building inventory are good for neighborhoods. The additional density of this form adds vital new life and energy. Areas are upgraded, adapted, and repurposed, maintaining the cultural value of the streetscape to the community, and preserving a sense of connection with the past.

Mass timber and light wood-frame assemblies should be considered for constructing additional stories on existing buildings, including interior and exterior load-bearing assemblies. The lightweight nature of wood structural systems can be an advantage by reducing the loads carried by the existing structure. In addition, performing a structural analysis may result in existing foundations requiring little to no reinforcement or modification, making adaptation and renovation a viable alternative for housing and much-needed rental density. The prefabricated nature of mass timber increases construction speed, and it reduces construction disturbances such as noise, dust, and traffic, as off-site prefabrication and just-in-time delivery methods are utilized.

OBC Part 10 (Change of Use) and Part 11 (Renovations) allow

some flexibility in maintaining and reusing existing buildings to preserve buildings’ existing appeal and provide owners with flexibility. However, moving from low-rise provisions into the mid-rise category of building typology (up to six stories) requires specific provisions in OBC

Part 3 to be met. This includes two means of egress from all floors, compliance with fire separation requirements, and sprinkler systems incorporated into the new floors, meeting NFPA 13 provisions for the newly created stories.

When planning a project, the vertical connection for exit enclosure fire separations is a significant consideration for the design team, particularly when adding stories to an existing building. From the late 19th to the early 20th century, many older buildings were constructed with one interior stairwell. A secondary exterior stairwell, sometimes called a “fire escape,” was provided as a second means of travel between floors. In providing two means of egress as required by the OBC 2012, both exit stairs must be in fire-rated and fire-separated enclosures, as per OBC 3.4.4.1. In the case of mid-rise buildings, the exit stair enclosure must be built with noncombustible materials.

Utilizing wood and mass timber assemblies in the design and construction of

the exit stair enclosures has the benefit of maintaining an all-wood building. Materials of similar properties, old and new wood in this case, work in synchronicity. New wood will quickly take on the moisture content and humidity of the environment. More rigid noncombustible materials can have a detrimental effect on how the existing structure behaves. The question will have to be asked early in the design phase as to how the existing wood structure could carry the noncombustible assemblies required. Switching between structural materials will require having another trade on-site, producing challenges with the construction schedule. This is a good case for wood enclosure assemblies, designed to achieve the required fire-rated performance, being raised during conversations with the AHJ.

Another point to consider is the connection points to old multi-wythe load-bearing walls that many older buildings are constructed with. These walls often contain much softer, more porous masonry than modern-day materials. This can have a significant impact when considering the interface of connecting rigid systems, such as steel and concrete, to older wood and heavy timber structures that have different ductility.

Wood systems can fully utilize the prefabrication process, a solution that reduces the time an existing building may be exposed to the effects of weather during construction. Craning already assembled components can be quick and efficient with the required planning, enabling additional stories and any prefabricated assemblies like exit stair enclosures to be positioned into place with precision. This minimizes moisture penetration and stops the existing structure from being damaged, such as any load-bearing masonry walls, existing timber framing, floor decking, and walls below. Careful planning and construction sequencing when removing an existing roof membrane and tying in the new structural systems to the existing structure must be carefully considered from the early design stages.

Steven Street is the technical manager with the Canadian Wood Council and Wood WORKS! Ontario.

Veronica Madonna is principal at Studio Veronica Madonna Architect and an assistant professor with the RAIC Centre for Architecture at Athabasca University.

Additional contribution from Robyn Huether, a heritage building consultant and principal at Robyn Huether Architect Inc.